MODEL MANUFACTURING

Aware that quality casting requires quality molds, we attach great importance to the production of molds with the correct dimensions and tolerances. Depending on the desired lifetime and the selected molding line, the models are made of wood, aluminum, iron or polystyrene.

ENGINEERING AND DESIGN

Optimized casting parameters and molding design increase our production efficiency by minimizing quality issues.

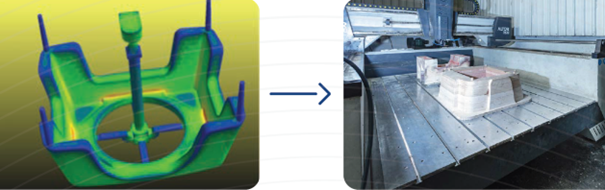

Topsolid and Solidworks programs are used as CAD/CAM software for determining part weights, designing 3D models and technical drawings of the parts to be cast. 3D modeling is the starting point of the simulation activity. Before the actual casting process, possible problems that may arise from the model design or casting parameters are identified and corrective actions are taken in advance to solve these problems. Anycast program is used as a simulation program.

All kinds of model production (Wood, Areldite, Al)

Solid model copying and processing with Cad/Cam program

Quikcast casting simulation program

2 pcs. vertical machining center600x700x450mm and 500x250x250mm

2 Vertical processing center 1200x700x500

The optimized parameters are then integrated into the product registration cards to ensure the best quality production during series production